Plastiblow blow moulding machines for medical articles production

In the medical field many articles are produced by means of blow moulding technology and using different polymeric materials: HDPE, LDPE, PVC, PET, PP, PC, EVA but also techno-polymers materials such as Teflon, polyeteramides and many others. The choice of the most suitable material holds a predominant importance, in particular when the application concerns the manufacture of a device that is in contact with the human tissue, or that must sustain continuous sterilizations in an autoclave.

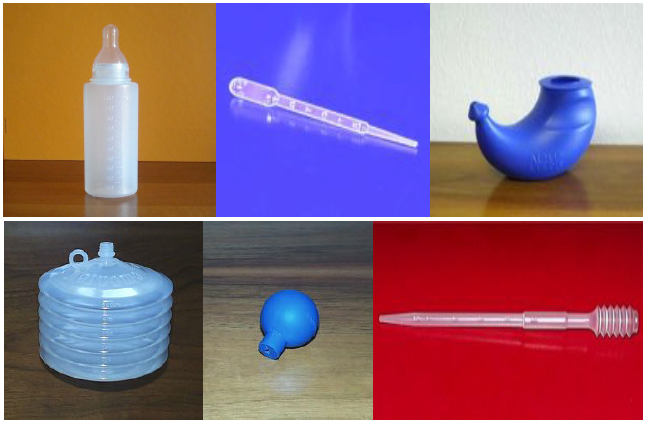

In the past years Plastiblow, well-known society from Milan, manufacturing machines for blow moulding of empty bodies, have designed many blow moulding machines for the production of medical articles such as test-tube and pipes for laboratory analysis, little pumps for ECG suction cups made in thermoplastic rubber, soft PVC bags and Teflon or Ultem articles for hospital use, inhalers and feeding-bottles made in Makrolon, polypropylene bottles for physiologic solutions, PVC dialysis tubes, as well as little bottle for pills, eye-wash or nasal drops made in PE, PVC or PETG. Each of these projects has produced specific problems of planning, design and setting, sometimes requiring the use of special metallic alloys suitable for very high working temperatures necessary for the processing of unusual plastic materials or specific automatisms for finishing, moving and packing of products of different shapes.

With the introduction of electrical drives Plastiblow blow moulding machines have further established in the field of medical articles because the total absence of hydraulic devices prevents any contamination of the products or of the environment and allows the use of the machine in sterile rooms or in controlled atmospheres.

The new generation blow-moulding machines have many advantages such as:

- Consistency of movements, because, without oil, there are no differences in movement when the working temperatures changes.

- More production, thanks to faster cycling and the reduction of production scrap due to more consistent movements.

- Lower running costs due to less energy consumptions

- Lower maintenance costs due to the lack of hydraulics components.

- Reduction of environment contamination due to the absence of oil and reduced noise levels.

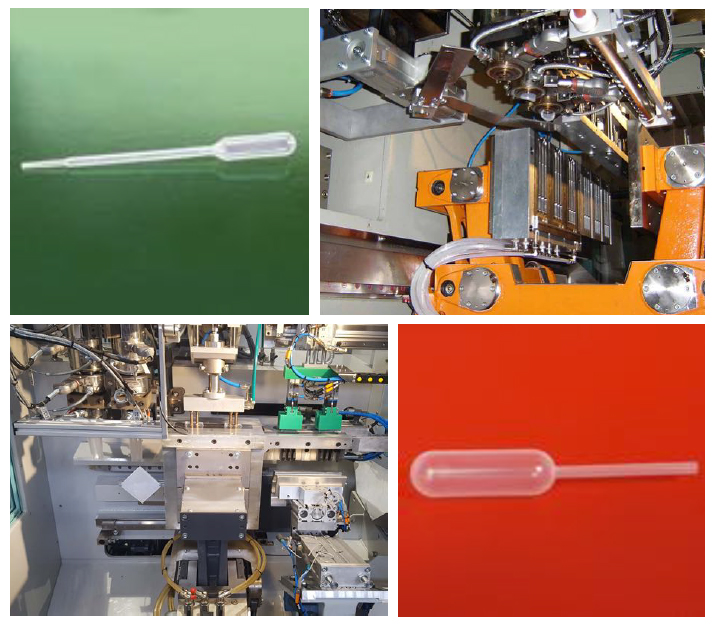

Examining for, instance, a specific article, Plastiblow has accumulated a remarkable experience in the manufacture of machines for the production of Pasteur pipettes, which are basically droppers for laboratory use so called after their inventor Louis Pasteur. The pipette is made by a thin capillary and a wider top that acts as a pump. The capillary part is engraved with a graduated scale, usually 1 to 3 ml. Pipette working consists essentially by crashing the dropper in order to make the air on the small pipe going out, and dipping it on the fluid. Releasing the pump there will be a lack of balance of pressure due so the fluid will rise in the tube and can not get out until the pump is once again crushed. Because of this function it is important that the material is sufficiently elastic and soft.

However, the production of the pipette by means of extrusion blow moulding involves the presence of sprue around the perimeter, and the sprue must be removed automatically in the machine. So it is appropriate that the material is also stiff enough to allow the operation of cutting scrap. In order to respect all these requirements, the pipette must be made with proper mixture of LDPE and EVA. In 1995 at Düsseldorf Show Plastiblow presented a blow moulding machine mod. PB250/S with three-cavites mould producing 2000 pieces per hour, then coming to realize machines for production of 16000 pieces per hour. For intermediate productions the most interesting electric blow moulding machine is a single station one, mod. PB2E/S, with 60 mm extruder and 3 outlets head for a production of over 6500 pipettes with a compact and easy to manage machine.

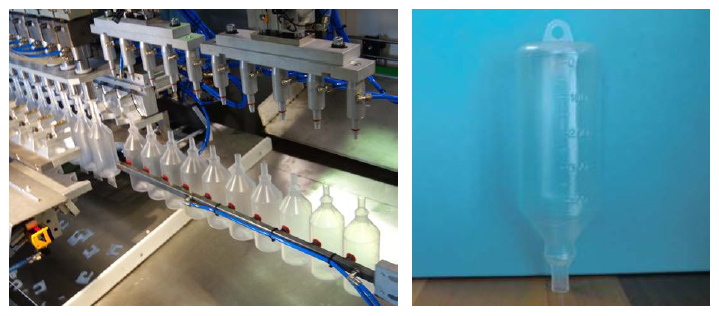

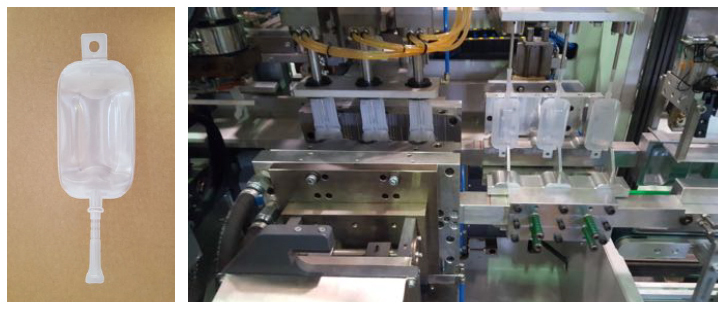

Other interesting applications refer to the packaging for parenteral solutions, where plastic bottles are quickly replacing conventional glass bottles, both for economic and practical reasons, resulting lightweight, unbreakable and easily transportable. The study of new shapes with limited thickness led to the production of collapsible bottles, such as flexible bags, but with more affordable costs.

For the production of bottles intended for infusion of intravenous liquid substances, various plastics can be used, mainly PP, LDPE or HDPE. These materials meet the requirements of the European and North American pharmacopoeia, having been approved and certified for use in parenteral liquid packaging. The choice of material is made according to the cost, availability, sterilization temperature and compatibility with the fluid to be packaged. Among the most recent achievements in the parenteral packaging sector are the following:

- a Plastiblow blow molding machine model PB26ED-800 E100/28 with a ten-outlet head for the production of around 6000 vials of 500 cc in PP random

- a double station blow molding machine model PB6ED-380 3+3 cavities for the production of LDPE bottles of 100 and 250 ml with the welded canula and delivered crushed to reduce the volume during transport.

Download pdf: artmed2018_en.pdf

For more information: plastiblow@plastiblow.it

.jpg)