PB2ES-PB2ED

Electric extrusion blow moulding machines • Stroke 200-260 mm

|

|

Single station |

Double station |

|||||

|

General data |

PB2ES-200 |

PB2ES-230 |

PB2ES-260 |

PB2ED-200 |

PB2ED-230 |

PB2ED-260 |

|

|

Moulds |

n° |

1 |

1 |

1 |

2 |

2 |

2 |

|

Stroke |

mm |

200 |

230 |

260 |

200 |

230 |

260 |

| Dry cycle time |

s |

1,1 |

1,2 |

1,3 |

1,1 |

1,2 |

1,3 |

| Motor clamping power |

kN |

1,4 |

1,4 |

||||

|

|

Single station |

Double station |

|||||

|

Consumptions |

PB2ES-200 |

PB2ES-230 |

PB2ES-260 |

PB2ED-200 |

PB2ED-230 |

PB2ED-260 |

|

|

Air pressure |

bar |

6 ÷ 8 |

6 ÷ 8 |

||||

|

Air consumption |

Nl/min |

500 |

1000 |

||||

|

Cooling water pressure |

bar |

3 ÷ 5 |

3 ÷ 5 |

||||

| Mould cooling HDPE |

KJ/Kg |

650 |

650 |

||||

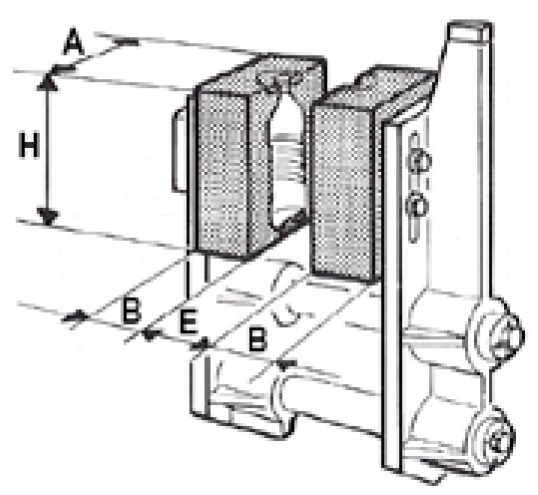

Mould

|

|

PB2ES-200 |

PB2ES-230 |

PB2ES-260 |

PB2ED-200 |

PB2ED-230 |

PB2ED-260 |

|

A mm |

220 |

240 |

280 |

190 |

220 |

250 |

|

H mm |

210 |

210 |

||||

|

B mm |

55 ÷ 65 |

55 ÷ 65 |

||||

|

E mm |

110 |

110 |

||||

|

CD |

CENTER DISTANCE | |||

|

N. Cav |

2 |

3 |

4 |

5 |

|

C = 200 |

65 |

40 |

- |

- |

|

C = 230 |

80 |

50 |

40 |

- |

|

C = 260 |

95 |

60 |

45 |

35 |

C = Stroke

|

Extruder |

E42/24 |

E50/25 |

|

| Screw diameter |

mm |

42 |

50 |

| Screw length |

L/D |

24 |

25 |

| Motor power |

kW |

9 |

18 |

|

HDPE plasticizing |

kg/h |

26 |

56 |

Dimensions and weight

|

|

Double station |

|

|

A x B x H |

|

C = 200 |

2540 x 2300 x 3700 |

|

4000 kg |

|

|

C = 230 |

2540 x 2300 x 3700 |

|

4000 kg |

|

|

C = 260 |

2540 x 2300 x 3700 |

|

4000 kg |

.jpg)